Why Steam Infusion?

Consumers all over the world want new indulgent, yet healthy food products at the best price but can existing food processing systems deliver?

Traditional steam jacketed vessels and steam injection systems haven't changed much over the last century but the demands of the forward-thinking food manufacturer have. New processing technologies can unlock new product development opportunities and achieve a step change in food processing efficiency.

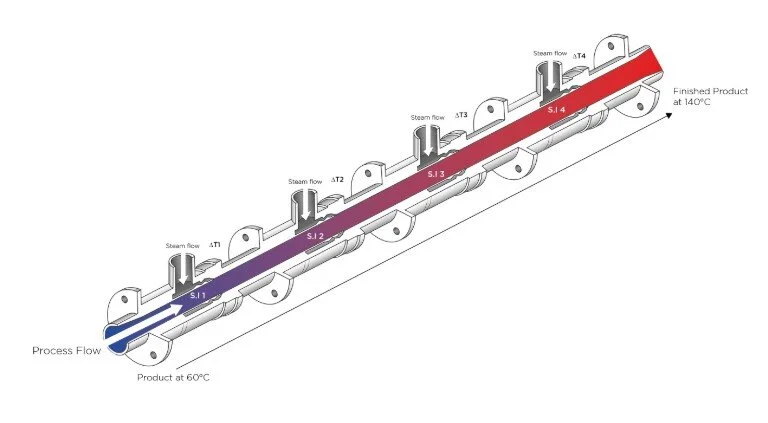

Steam Infusion is a simple disruptive cooking process that helps food manufacturers overcome many of the challenges they face every day including burn-on contamination, variable product consistency and slow cooking times.

Forward-thinking food manufacturers are using Steam Infusion to cook over 210,000kg (231.5 US t) of high quality soups, sauces and ready meals every day. With Steam Infusion they've unlocked profitable new product categories and highly efficient cooking while reducing energy consumption by up to 20%.

Discover how Steam Infusion can help you

What our customers say...

“The Steam Infusion system is very fast and has reduced our cooking energy consumption by 15%. It’s a quality piece of equipment that’s definitely ‘cook proof’.”

“Steam Infusion has reduced the production time of our soups and sauce by more than 50% as well as reducing energy whilst still maintaining our exceptional product quality.”

Steam Infusion adopters include:

Latest updates

Steam Infusion can produce an homogenising effect but does this mean that you no longer need a homogeniser? Here we explore what Steam Infusion can achieve and how we can optimise your products.

Many savoury recipes require caramelisation of different ingredients. Unfortunately Steam Infusion cooking doesn't expose ingredients to excess temperatures, therefore it can’t caramelise any ingredients - here we explain how to work around the challenge.

New research spearheaded by the National Centre for Food Manufacturing (NCFM), University of Lincoln, has found that Steam Infusion can reduce energy consumption by 17% per batch compared to basic direct steam heating by saving 278 hours of production time, cutting 9 tonnes (10 US tons) of greenhouse gas (GHG) emissions per kettle production line each year.

One of the first questions many food manufacturers ask when exploring Steam Infusion is how much does it cost? The final cost of integrating into new or existing cooking vessels is influenced by a number of factors; here we explain the general costs of adopting Steam Infusion cooking.

Heat exchangers are ubiquitous in the food industry and in many instances are the right tool for the job, but we’re sure you’ve also suffered some pain when using them. Here are our top 3 reasons for switching from heat exchangers to Steam Infusion.

'Chunky' products are a great way to stand out on the shelf, but not every processing technology can handle the chunks. However, with Steam Infusion, you can heat products with particulates up to 20mm (0.79 in), from meat to vegetables and fruit while maintaining the integrity, delivering a final product that consumers will love.

Sauces; they’re a staple of the British diet. From traditional family favourites like ketchup to new exotic flavours and concepts, these additions to our meals are becoming the star of the show, according to The Grocer. So how can manufacturers get a ‘splash’ of the action?

Ready meals are big business and consumers are seeking more authentic flavours from the ready meals they choose. But while flavours are getting bigger, government bodies are cracking down on salt, sugar and calories. This poses the challenge – how do manufacturers meet the targets without compromising on taste?

One question we’re often asked is how can we calculate the amount of steam added into my product and whether adding in steam has any effect on the taste or texture. Read on to find out more!

We’re delighted to announce our partnership with Spirax Sarco, the steam experts. They will now be offering our Steam Infusion technology and Vaction™ Pump to food & beverage manufacturers is various locations around the world. We kicked off our partnership with a pair of webinars to explain how this innovative technology works.

Whether it’s demands from consumers or governments, the food industry is under huge pressure to reduce its carbon footprint. What if there were a way to cut energy consumption while actually increasing your throughputs? Steam Infusion could be the answer.

Frozen food is enjoying something of a renaissance. No longer relegated to the bargain basement, consumers are waking up to frozen foods. UK shoppers spent nearly £1 billion more on frozen food in 2020 – 15.1% growth in value [Kantar 52 w/e 27 December 2020], so manufacturers are eager to take advantage of frozen. But how can you ensure the flavours meet consumers’ expectations?

As a nation of ready meal lovers, the UK is one of the most developed markets for these convenience products. But it seems the tide is turning. According to The Grocer, UK sales of chilled ready meals fell by £75m in 2020. But is this trend here to stay or can manufacturers bring back shoppers?

On est ravi de vous annoncer notre partenariat avec Spirax Sarco France, les experts en vapeur. Maintenant ils offrent notre technologie Steam Infusion et la Pompe Vaction™ aux producteurs agroalimentaires partout dans la France. On a commencé avec un webinaire pour expliquer comment marche cette solution innovante.

Pasta. The food of love. And according to a report in The Grocer in November 2020, pasta consumption is through the roof in the UK following successive lockdowns during the pandemic. It seems we Brits just can’t put down the penne… or the pasta sauce.

Veganuary is the new mega-trend. As almost 600,000 people signed up to Veganuary in 2021 (more than double the number who pledged in 2019) from all corners of the globe, have you made your mark on the plant-based aisle?

Viscous sauces can be a real winner. Whether it’s a creamy dessert or a thick savoury sauce, the right viscosity can attract consumers. But they can be tricky to cook, often suffering from burn-on with traditional technologies and subsequently proving difficult to clean. So how can food manufacturers overcome these challenges and still delight their customers?

We’re pleased to announce our new partnership with Spirax Sarco Nordics, experts in steam system solutions . The company now offers our Steam Infusion Vaction™ Pump technology to food and beverage manufacturers across the region following the successful completion of several projects.

As more and more consumers are choosing vegan products, we’re facing a new challenge – how do we consume sufficient protein to maintain a healthy diet? A growing body of evidence is advocating for manufacturers to create new plant-based protein-fortified products to support consumer health. But what are the challenges when engaging in NPD in this area?

In a first for OAL, we have installed multiple Steam Infusion cooking systems in China, helping manufacturers to improve standardisation and repeatability in their processes. Using OAL equipment and expertise, state-of-the-art plants will now manufacture high-quality products for customers right across China.

Veganism has exploded in popularity in recent years and dairy-free is leading the way, making up the largest category of the plant-based segment. However, for manufacturers looking to capitalise on this trend, finding the right processing equipment can be difficult. So how can this nut be cracked?

According to The Grocer, the cost of spices is surging in 2019 due to a number of global weather issues. Cardamom saw a 30% spike in prices in 2019, reaching an eight-year high, while vanilla now costs more than silver. So can you prevent these price rises hitting your bottom line?

For many manufacturers, effluent is part of day-to-day life but it can often feel like a drain on your business. However, what if we told you there’s a way to not only reduce the amount you pay in trade effluent charge by up to 80% but also increase productivity while improving energy efficiency?

The first Steam Infusion system has been installed in Australia following the announcement of our partnership with Process Plant Network (PPN) in early 2019. The patented cooking technology has helped PM Fresh, an Australian food manufacturer, grow its high-quality sauce business with lucrative new contract wins.

Steam Infusion can change your flavours if you want it to. By varying the steam pressure, the Vaction™ Pump can achieve two different results; emulate steam injectors to achieve product matching or create unique conditions for new product development, delivering fresh, home-made flavours that consumers will love.