Top 3 reasons to switch from heat exchangers to Steam Infusion

Heat exchangers are ubiquitous in the food industry and in many instances are the right tool for the job. They can be ideal for your processing needs as well as great for energy efficiency as they reuse heat generated within your facility. But we’re sure you’ve also suffered some pain with your heat exchangers and unfortunately they may not be able to process every product. If you’re having problems, In-Line Steam Infusion could be the alternative you’re looking for. Here are our top 3 reasons for switching from heat exchangers to Steam Infusion.

1) Maintenance

Heat exchangers are a familiar solution in the world of food processing. But as you will know, the challenges they cause can be a real headache. From blown gaskets to misaligned plates or blocked tubes and burn-on, many will associate heat exchangers with downtime and the need for regular maintenance – as well as the costs that go hand in hand with these difficulties.

If you’re using manual heat exchangers, you may have struggled with misalignment and over-compression and the associated damage, lost production time or even product recalls if your CIP processes fail. With scrape surface heat exchangers, if the scrapers aren’t replaced frequently enough, they wear down and lose their ability to scrape - a self-cleaning action. If this happens, product will start to burn on to the inside of the exchanger, which can lead to serious issues like loss of heat transfer, not to mention the product safety and quality issues associated with this. What’s more, without regular inspections, problems can build up and the scrapers may stop moving, leading to downtime and inconsistent batches.

Manufacturers using heat exchangers must also face the cost of spare parts and servicing. Heat exchanger manufacturers recommend that you conduct maintenance daily, weekly, quarterly and annually if you want to get the best out of your equipment – that’s quite a lot of downtime, although not nearly as much as if you didn’t conduct any maintenance, not to mention the cost of repairs.

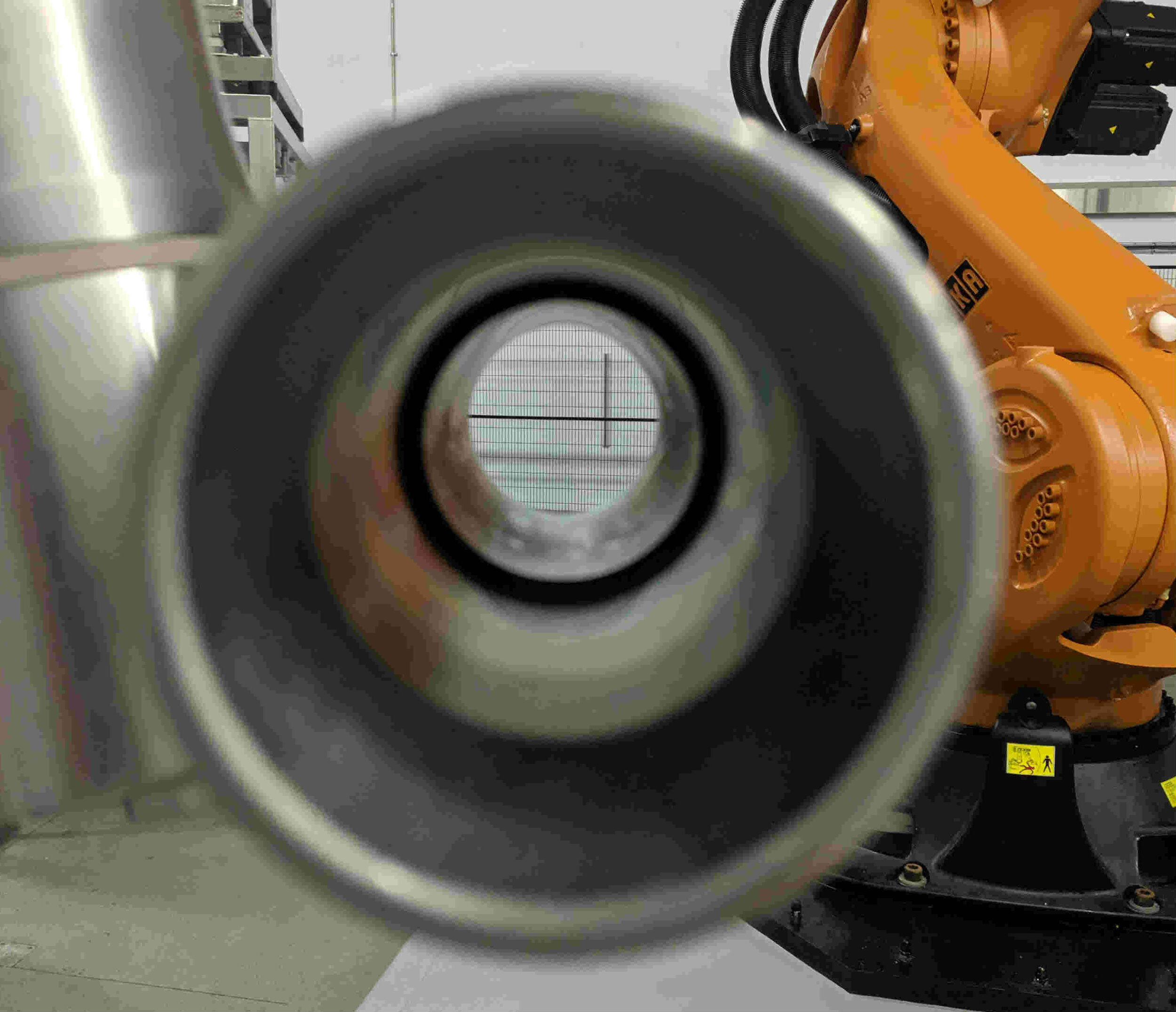

Fortunately with Steam Infusion, manufacturers can benefit from near maintenance-free operation. With no moving parts in the product flow, Steam Infusion offers the ultimate reliability; we have a number of customers who have been using their Vaction Pumps 24/7 for over ten years without any need for maintenance or replacement Vaction Pumps. What’s more, our Steam Infusion Vaction Pumps are made of a single piece of 316L stainless steel so you’re not faced with an endless list of spare parts to stock. Not only does this remove the potential for unplanned downtime, increasing your efficiencies and output, it can also result in significant annual cost savings thanks to reduced maintenance and removal of condensate management.

2) Hygiene

Clean in place (CIP) processes are vital in food production for consumer safety but it can be a particular challenge with heat exchangers. For example, with scrape surface heat exchangers, the product can burn on to the scrapers so CIP processes must be conducted regularly, usually at least twice a day depending on your volumes. With tube in tube heat exchangers, pipework can get blocked up by product build-up and products may fail safety checks due to contamination from the burn-on or residue.

With Steam Infusion, burn-on is eliminated, protecting the product itself as well as all of the equipment, allowing manufacturers to conduct a full CIP less regularly. As you can see in the caramel sauce video, after cooking a sticky, sugary sauce, a simple rinse is all that’s needed ahead of the next batch. This can be confirmed by our customer in Spain as they discovered when they were able to cut their full CIP process from every two batches to every 10! If you’re running a single product continuously, a CIP may not be needed until defined as part of your cleaning schedule.

3) Processing limitations

Closely linked to point two, processing limitations can occasionally arise when using heat exchangers. They’re not the most flexible pieces of equipment, which is difficult in the food industry where product changeovers are standard, particularly with the need for smaller batch sizes to cater for the ‘batch of one’ trend. They’re also fairly large and costly, so if you win a new contract and need to increase production, it can lead to a significant investment, both in terms of money as well as factory space.

What’s more, tube in tube heat exchangers can’t process particulates as they would cause blockages, limiting the products your NPD team can develop, potentially damaging sales. There can also be a lot of waste, either due to product lost in pipework or because of burnt product.

The Multi-In-Line Steam Infusion system can help to overcome these processing challenges. Steam Infusion offers you complete flexibility whether you’re processing continuously or in batches. With Steam Infusion you can double your production capacity with minimal investment using your existing equipment to meet increased demand within the same footprint. Your NPD team can let their imagination run wild - with Steam Infusion you can create products that will tap into consumer demand, no matter the composition. ‘Chunky’ varieties are easy to produce with Steam Infusion as particulates up to 20mm can pass through undamaged - take a look at our strawberry sauce video. What’s more, with no burn-on, no product is wasted - better for the environment and your bottom line.

Steam Infusion can be the solution to the challenges of using heat exchangers, including maintenance, hygiene and processing limitations. We have customers who have switched to In-Line Steam Infusion following trials of their products; we have process engineering experts and development chefs who can advise on the best approach to optimise your NPD or ensure a seamless switch for your existing products.