What’s the difference between jet cook and Steam Infusion?

You may have heard of jet cook or jet cooking and wondered what the difference is between that technology and Steam Infusion. When it comes to direct steam injection technology, there are a whole host of different solutions on the market so here we break down these two technologies to help you understand which is the right one for your processes.

What is jet cook?

ProSonix’s Jet Cooker

Jet cook has been around for many years. A jet cooker or steam jet cooker is a form of steam injection primarily used in starch cooking, wet mill processing of starch, ethanol production or fructose and alcohol production. The system injects steam into the starch or grains as it is pumped through an orifice at high pressure. High shear is created thanks to the high turbulence and the large pressure drop that is generated in the process, which works at elevated temperatures, over 100°C (212°F) and up to 145°C (293°F). The jet cook system can be used to break starch down into sugars when used in conjunction with the right enzymes, so it is often used in whisky production, and to develop sugar syrups and sweeteners.

However, jet cooking does generate high shear stress to starch. It was reported in Procedia Food Science Journal in 2011 by Fernga et al that the shear force caused by steam jet cooking of corn starches results in significant destruction of the granules. A comparison between hot water boiling and steam jet cooking at 100°C (212°F) demonstrated that starches heated by steam jet cooking were fractured into small fragments, but the degree of destruction relates to the amylose content of corn starch.

This destruction of starch can have a negative effect on shelf life causing syneresis, where the liquids contained in the starch separate from the product and collect on the surface. It can also affect dairy-based sauces, such as hollandaise or béchamel, causing them to ‘break’ as the starch no longer binds them together. For this reason, it is not a suitable process for the majority of food products where starch is included.

What is Steam Infusion?

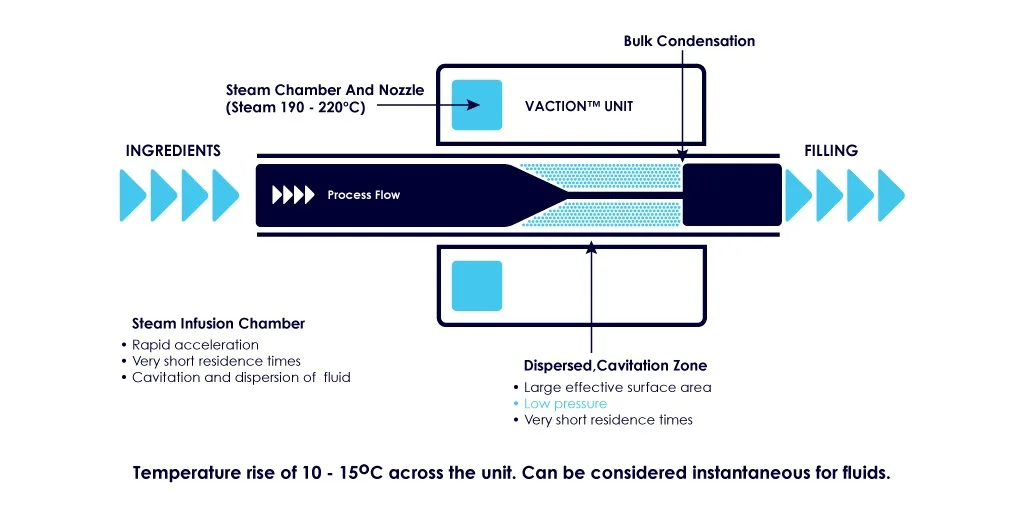

Like jet cook, Steam Infusion is a form of steam injection, however the patented design of the Steam Infusion Vaction™ Pump uniquely introduces steam, achieving a wider operating envelope and delivering a number of processing improvements, namely:

Elimination of burn-on or Maillard reactions

Processing of particulates up to 20mm (0.79in)

A controllable shearing effect

Steam Infusion uses steam as the motive force but thanks to the geometry of the pump, it can heat, mix and pump liquids with and without particulates. Steam is introduced into any liquid via the patented Steam Infusion Vaction™ pump, in which the profiling accelerates the velocity of the steam to 1,000m/s (3280 ft/s) – above the speed of sound. The steam passes into the mixing chamber through an annular nozzle disrupting the fluid flow to form small droplets, referred to as the vapour phase. The momentum transfers from the steam to the product and creates a partial vacuum of -0.7barg (-10.1psig) within the unit and, depending on the configuration of the engineered system and the needs of the application, can also reach temperatures of 145°C (293°F). Despite the high temperatures, no burn-on is left on the product and there is no presence of syneresis when used at temperatures below 100°C (212°F).

Unihibited bore on an In-Tank Steam Infusion Vaction pump

Thanks to the uninhibited bore, liquids and particulates can pass through the pump without any damage, even with the velocity of the steam. The core operating principle of Steam Infusion is that of disruption, which is controllable, enabling standardised batch cooking time and time again. By varying the steam pressure used with Steam Infusion, from 2.0barg (29psig) to 6.0barg (87psig), we can vary the shearing effect. If low shear is required, low pressure steam is introduced, but if you are looking for a higher shear, we can take the pressure up to the maximum. This controllable shearing effect ensures Steam Infusion can gently yet rapidly cook a variety of food ingredients and products including desserts, soups and sauces.

What’s right for your process?

So what do you need? If you’re looking to cook starches in the production of whisky or sugar products, then either solution could be right for you. However, if you’re looking to cook a wider range of food and beverage products and want to achieve fast cooking, avoid burn-on contamination and improve consistency then it might be worth exploring Steam Infusion.