What’s the difference between Steam Infusion & direct steam injection?

One question we’re often asked by food manufacturers is how does Steam Infusion differ from direct steam injection? If you’re already using steam injection then the good news is Steam Infusion is a straight swap for your current system. If you’re new to steam cooking, there are a couple of considerations. For example, it’s necessary to have culinary grade or clean steam on site to ensure your steam is free of contaminants and therefore safe to use in food products: will this be possible in your existing site? Then a choice needs to be made: what method of delivery is to be used? Steam injection or Steam Infusion? Here we take you through the main areas you need to consider when evaluating the different technologies.

1) Speed of cook

The key difference between steam injection and Steam Infusion is the speed at which steam is introduced into the product and the resulting operating conditions and cook time.

Direct steam injection

Direct steam injection takes various forms either adding steam through apertures around the skin of the vessel or through a lance positioned inside the vessel. It involves discharging a series of steam bubbles into the product. Steam injectors are engineered to create a turbulent zone within the steam injector body to help mix the steam and product. This allows for slightly higher operating steam pressures than a rudimentary sparge pipe. One of the key challenges around efficiency is that steam bubbles can easily reach and break the surface, escaping to atmosphere, lengthening your cook time and increasing wastage.

Steam Infusion

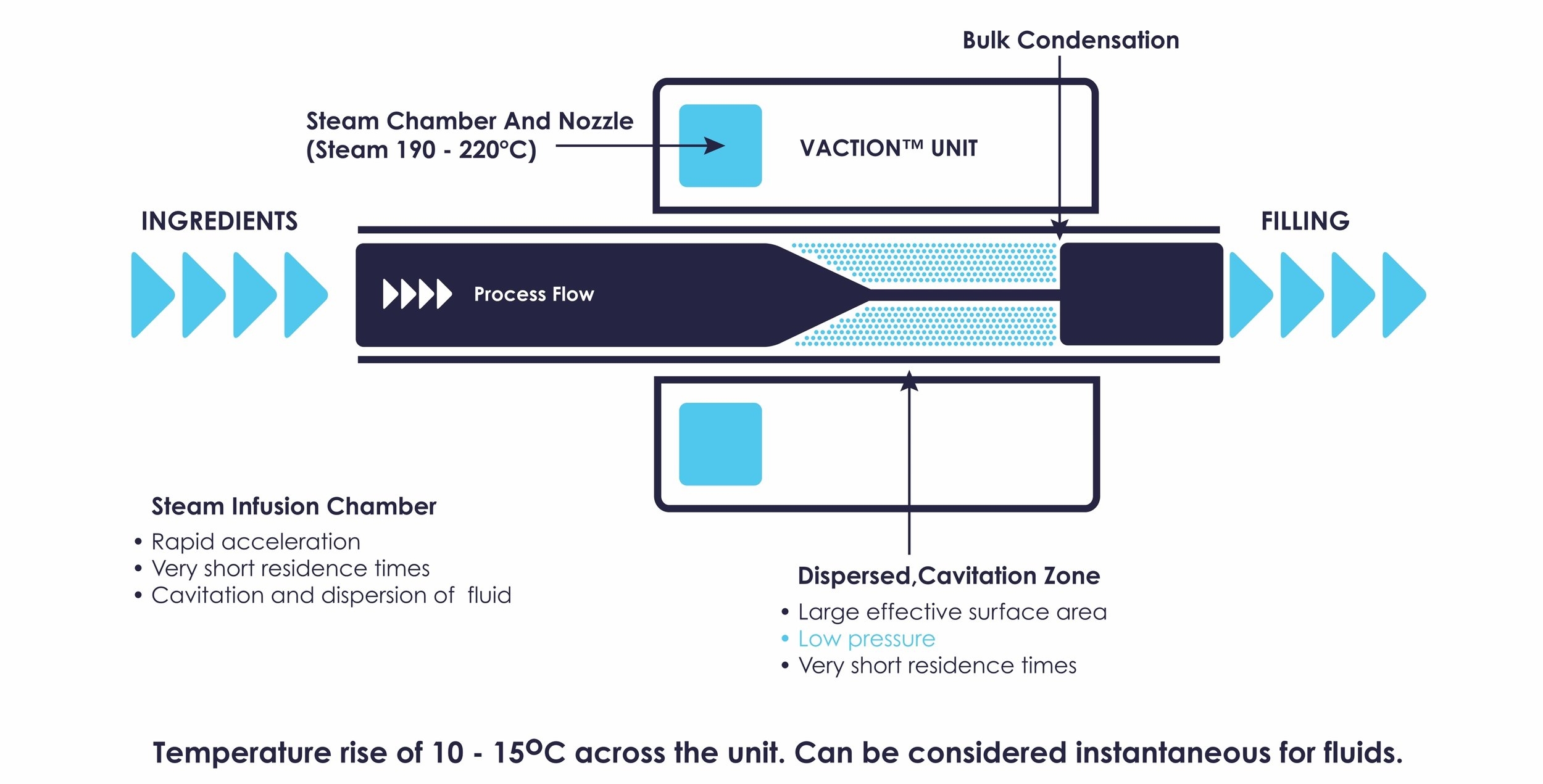

In contrast, the Steam Infusion Vaction unit accelerates steam into the product at speeds reaching 1,000 m/s (3,280 ft/s) disrupting the product in the process. Special profiling within the Vaction™ Pump steam chamber accelerates the velocity of the steam to above the speed of sound. As the steam passes into the mixing chamber through an annular nozzle, the steam disrupts the fluid flow and breaks it into small droplets, referred to as the vapour phase.

The small droplets within the low pressure vapour phase offer a significantly increased product surface area for the steam to condense into, resulting in a temperature gradient in the order of 12°C (54°F). This ensures there are no hot surface contact / hot spots, thus preserving the quality of the product and eliminating Maillard reactions and caramelisation of certain sugars i.e. no burn-on.

2) Heating speed/efficiency compromise

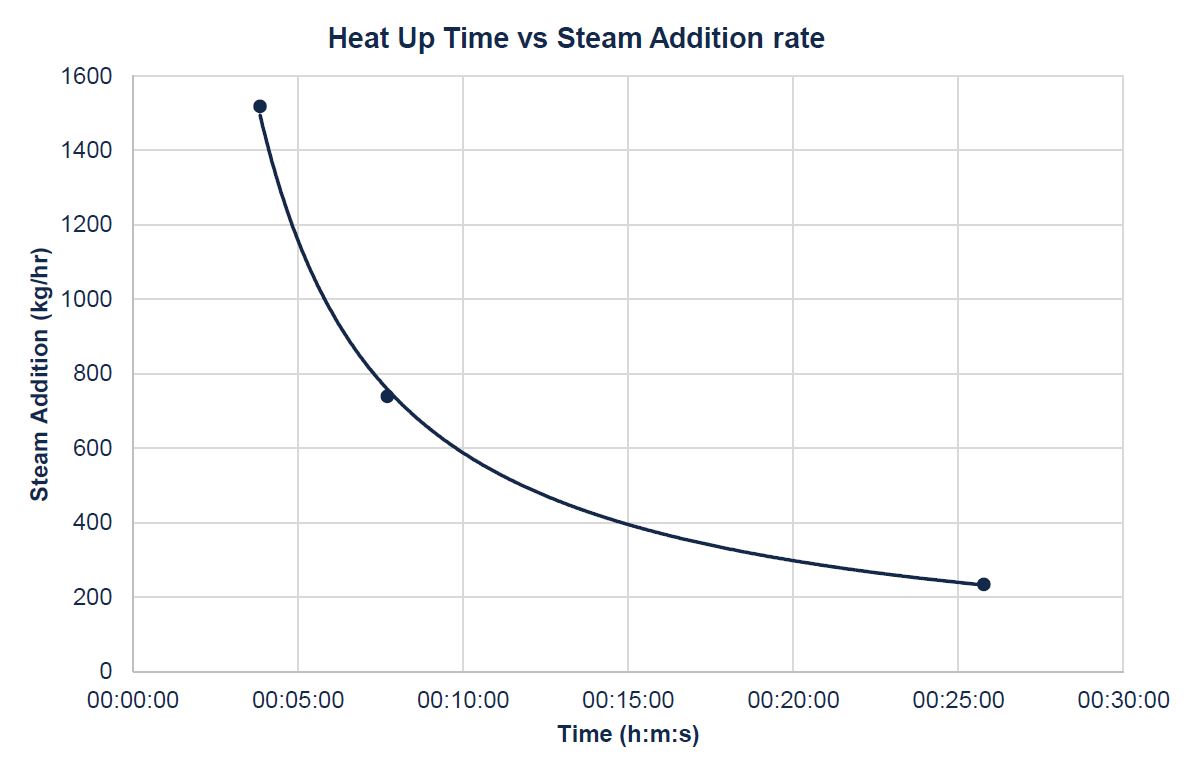

Traditionally, when heating with direct steam injection there is a compromise between heating speed and efficiency. With Steam Infusion, food manufacturers can overcome this compromise as the disruptive processing environment decouples steam addition rate from inefficiency.

Steam injection

Direct steam injection tends to be used to speed up heating times. However, because of an inversely proportional relationship as steam pressure is changed, it doesn’t meet this objective. If the pressure is increased, the contact time is reduced as flow rates increase and steam fails to fully condense. In this scenario, it remains in a gaseous state and exits the system as steam; wasting energy and water, as well as slowing down the process. This inefficiency will increase as the temperature difference between the product and steam reduces and can also lead to increased variability within each batch as it’s hard to create consistency within the cooking process.

Steam Infusion

However, with Steam Infusion, the heating process does not rely on contact time between the steam and the product thanks to the annular design of the Vaction Pump allowing steam to condense within the unit itself. This means that Steam Infusion has the ability to run at comparatively higher steam pressures without compromising on efficiency.

As Steam Infusion maintains complete retention of the steam, it means that it’s not only faster and more efficient, it is also easier to control.

3) Product appearance

Steam injection

One of the key challenges with direct steam injection is the exposure of your product to high-temperature steam. This can result in fouling and discolouration of delicate dairy sauces such as béchamel sauce, or tomato-based sauces turning orange.

Steam Infusion

Steam Infusion, on the other hand, prevents exposure to excessive temperatures and the resulting Maillard reaction because of the partial vacuum generated by the Pump as it heats, mixes and pumps products within the vessel. In this way, it’s possible to avoid this discolouration and create a product that’s much more attractive to consumers.

The supersonic steam flow entrains and vaporises the product flow to form a multiphase flow, which heats the suspended particles by surface conduction and condensation. This causes rapid and uniform heating over the unit in a temperature gradient in the order of 12°C, ensuring there are no hot surface contact or hot spots so manufacturers can preserve the quality of the product and eliminate Maillard reactions and caramelisation of certain sugars. This can be extremely useful, particularly from a development perspective, as products appear cleaner and are a better match to the concept sauce cooked in a traditional kitchen set-up. It also allows manufacturers to tap into the trend for ‘home-made’ style products as it’s easier to achieve this result with Steam Infusion.

4) Cleaning & downtime

Cleaning

Steam injection relies on complex mechanical assembly with multiple voids and surfaces, which leads to inherent cleaning challenges. Unfortunately, this means more downtime as cleaning must take place after each batch. However, because the Steam Infusion Vaction pump has no moving parts, manufacturers benefit from near maintenance-free operation. The simplicity of the unit means that it is an inherently clean design. This facilitates cleaning in place (CIP) when it’s necessary and because there is no risk of burn-on, the automated CIP or manual clean process is much quicker as there is no burnt-on product to remove. In addition, the lack of burn-on means it’s possible to perform more back to back cooks with a Steam Infusion system without the possibility of burnt contaminants appearing as flecks within the product.

Downtime

Minimising plant downtime is priority for food manufacturers, many of whom are operating at full capacity. Steam injectors are normally installed in the vessel jacket leading to complex installation on retrofits and can mean significant downtime while the project is completed. The Steam Infusion lance is simpler as it can be mounted onto the vessel lid in vessels with inclined agitation, resulting in minimal downtime, or it can be integrated in-line in your process. There is virtually no maintenance involved in the operation of Steam Infusion Pumps so you can keep running your operations without factoring in costly downtime.